Modular Expandable CNC Lathe Structure: A Full Overview of Force One FCL Series Slant-Bed Machines

Aug 11 2025

Aug 11 2025In today’s era of high-mix, low-volume, and diversifed manufacturing, CNC lathes are no longer merely fxed-confguration equipment—they have become scalable modular platforms. Force One FCL Series slant-bed precision CNC lathes are built with this exact logic in mind. Based on a highly standardized slant-bed structure, the series offers modular expansions including spindle, turret, Y-axis, C-axis, and sub-spindle, enabling each lathe to flexibly handle diverse applications from one-off prototyping to complex mill-turn operations in production lines.

FCL Series Slant Bed

Modular Design: Slant Bed × Flexible Expansio

The FCL Series features a core 45° slant bed platform, providing all models with consistent performance in rigidity, chip evacuation, and stability. This architecture supports the following modular expansion options:

| Module Type | Expandable Options | Purpose & Benefts |

|---|---|---|

| Sub-Spindle Module | Standard Spindle / Sub-Spindle | Enables front-and-back machining in a single setup, improving automation |

| Turret Module | Single Turret / Twin Turret | Parallel machining enhances efficiency and distributes tool load |

| Live Tool Module | With C-Axis Control | Supports face machining, milling, and tapping |

| Y-Axis Module | Eccentric / Mill-Turn | Increases geometric freedom for complex parts, reduces machine switching |

| Auto Loading Module | Robot Arm System | Enables automated loading/unloading for unmanned production |

All expansions are built on the same slant-bed structure, highlighting adjustability and flexible confguration, thereby reducing the tooling burden on the production end.

Decoding the Model: Understand the Code, Know the Confguration

The FCL Series model codes represent the modular confguration of each machine. Below is the reference table:

| Model Code | Spindle Confguration | Turret Type | Y-Axis Travel | C-Axis Control |

|---|---|---|---|---|

| FCL | Single Spindle | Non-Live Turret (opt. Live Turret) |

No | No |

| FCL-Y | Single Spindle | Live Turret | Yes | Yes |

| FCL-TS | Twin Spindles | Non-Live Turret | No | No |

| FCL-TSY | Twin Spindles | Live Turret | Yes | Yes |

| FCL-TT | Twin / Single Spindle (opt.) | Twin Turrets | No | No |

| FCL-TTY | Twin / Single Spindle (opt.) | Twin Turrets (Live Turret) | Yes | Yes |

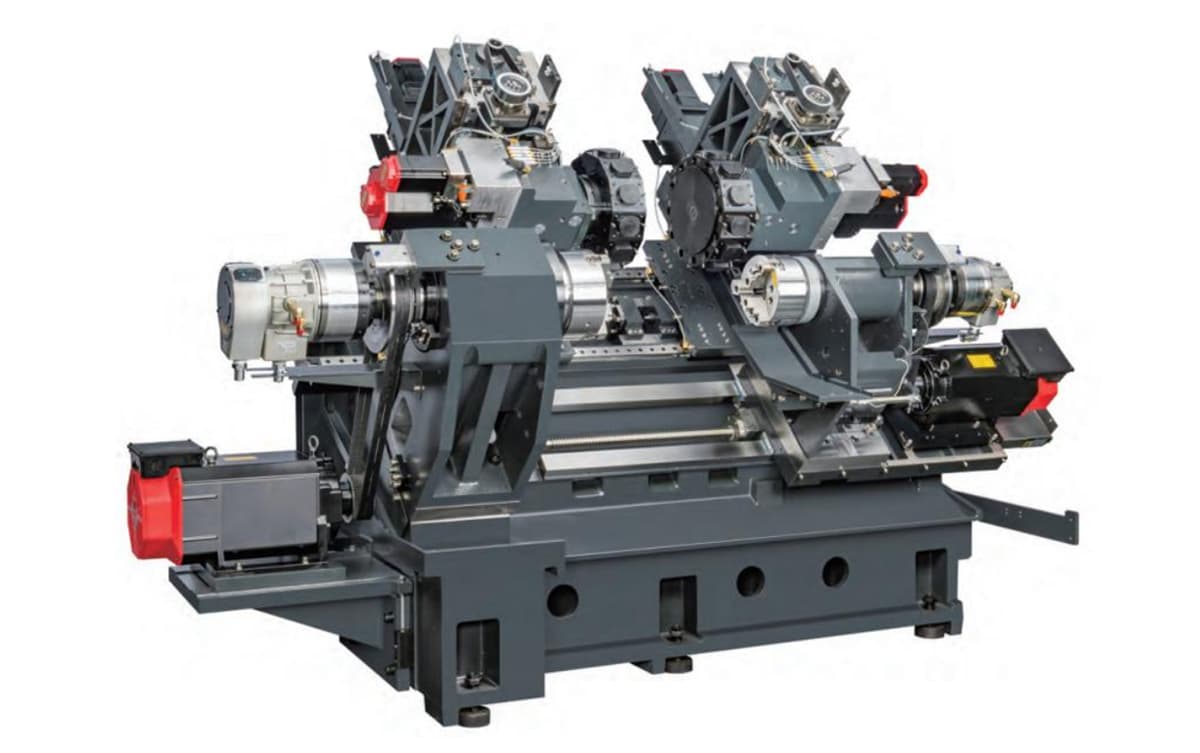

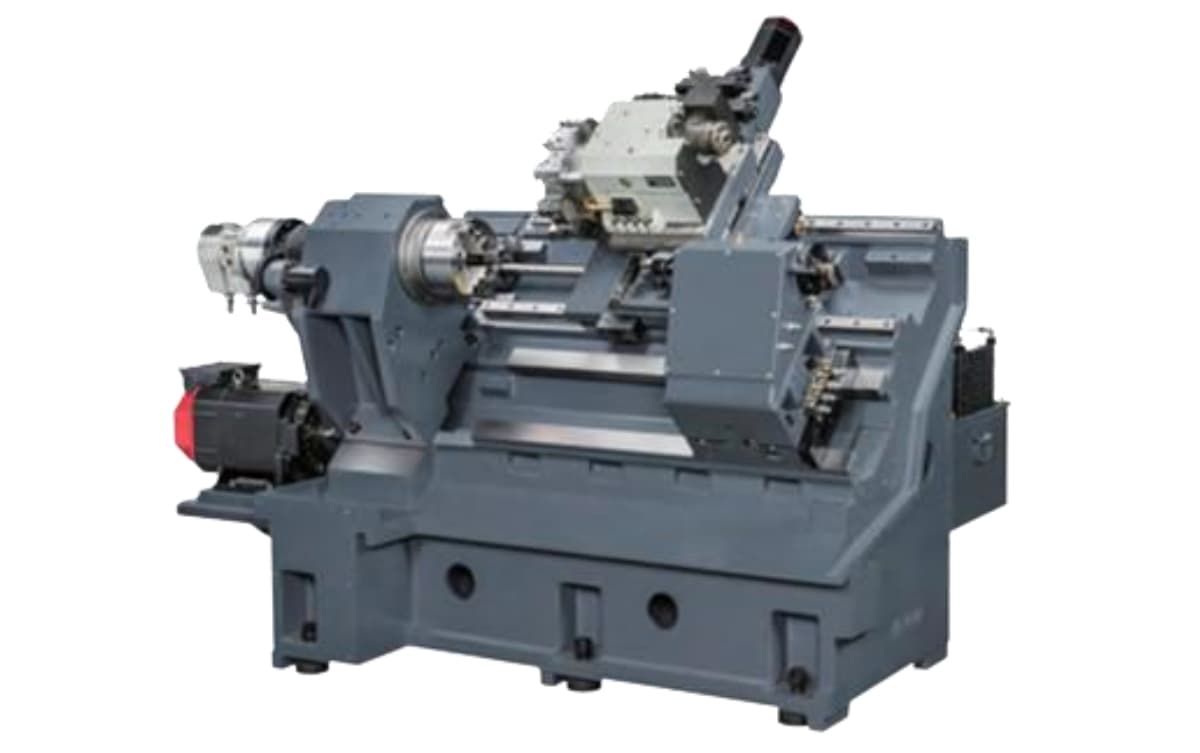

FCL Standard Confguration

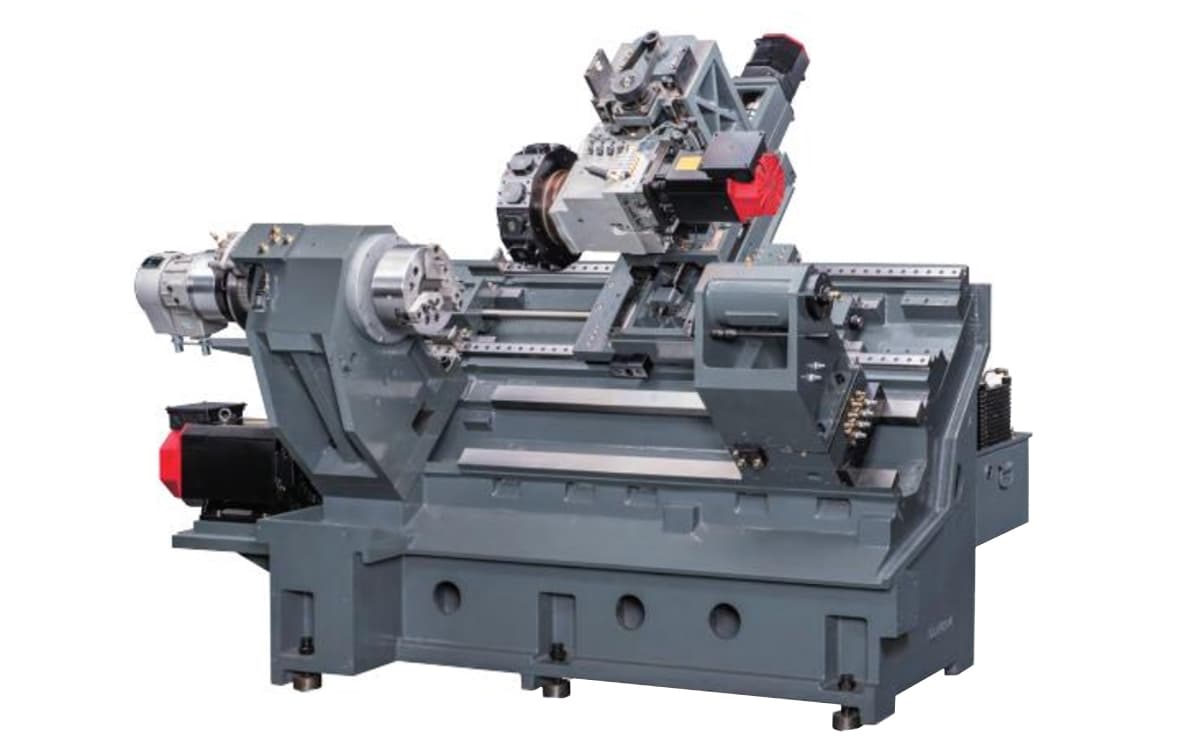

FCL-Y Series (opt.)

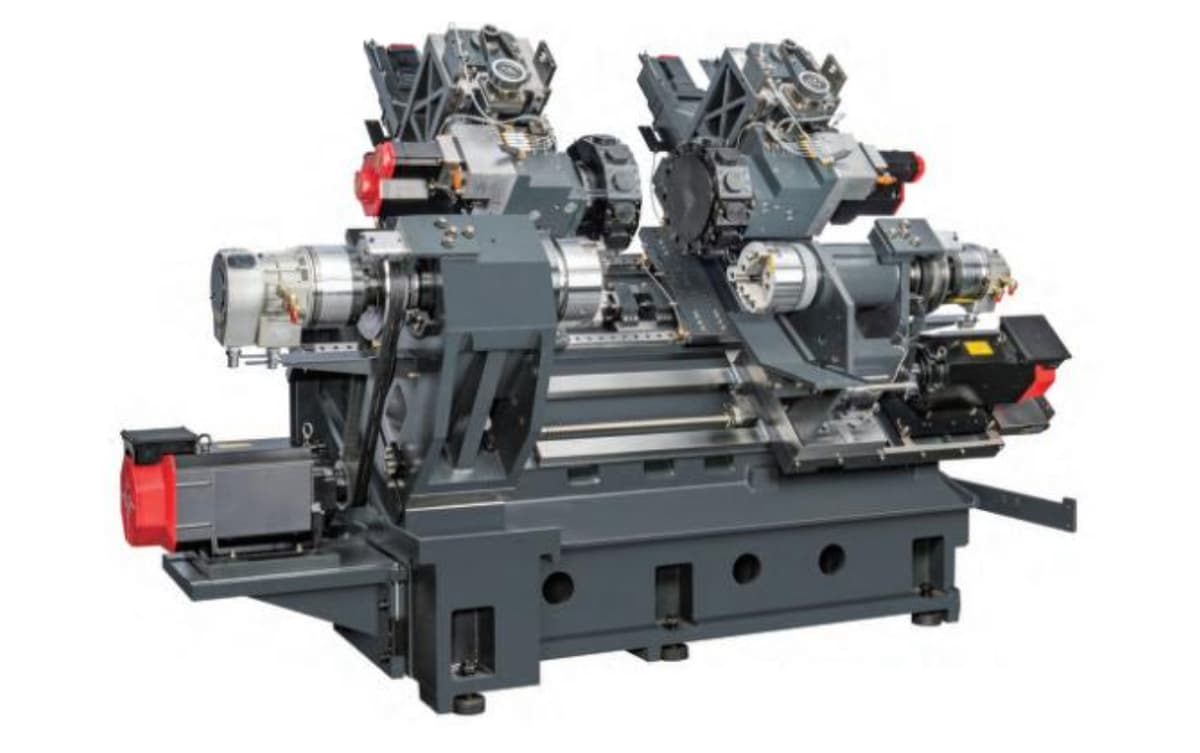

FCL-TTY Series (Twin Turrets / Twin Spindles / Y-Axis opt.)

Modular Matching × Workpiece Needs: Model Selection Guide

| Machining Requirement | Required Modules | Recommended Models |

|---|---|---|

| Basic OD / Face Turning | Standard Spindle + NonLive Turret | FCL Standard Model |

| Fast Cycle Time, Multiple Operations | Twin Turrets Series | FCL-TT, FCL-TTY |

| Front and Back Machining in One Setup | Sub-Spindle | FCL-TS, FCL-TT, FCL TTY |

| Axial Drilling, Tapping, Mill-Turn | Live Tool + C-Axis | FCL(M), FCL-TS, FCL-TT |

| Eccentric Drilling/Tapping, Complex Milling | Y-Axis + Live Tool + CAxis | FCL-TSY, FCL-TTY |

| Automation / Lights-Out Machining | Robot Arm Interface + Sub-Spindle | All FCL Models |

With flexible module confgurations, the FCL Series is not just a machine—it's the core of your process solution.

FCL Is a Modular Mindset, Not Just a CNC Lathe

The key strength of Force One FCL Series lies not in any single model’s specifcations, but in its design philosophy: modularization and standardization. Each FCL machine can be custom-confgured during the build stage to match real-world machining requirements—avoiding over-specifcation and waste.

If you’re looking for a CNC lathe that can be truly tailored to your needs, the modular architecture of the FCL Series is your most dependable choice.

Back

Back