How to Set Cutting Parameters in CNC Turning? Mastering the Golden Rules of Speed and Feed

Oct 14 2025

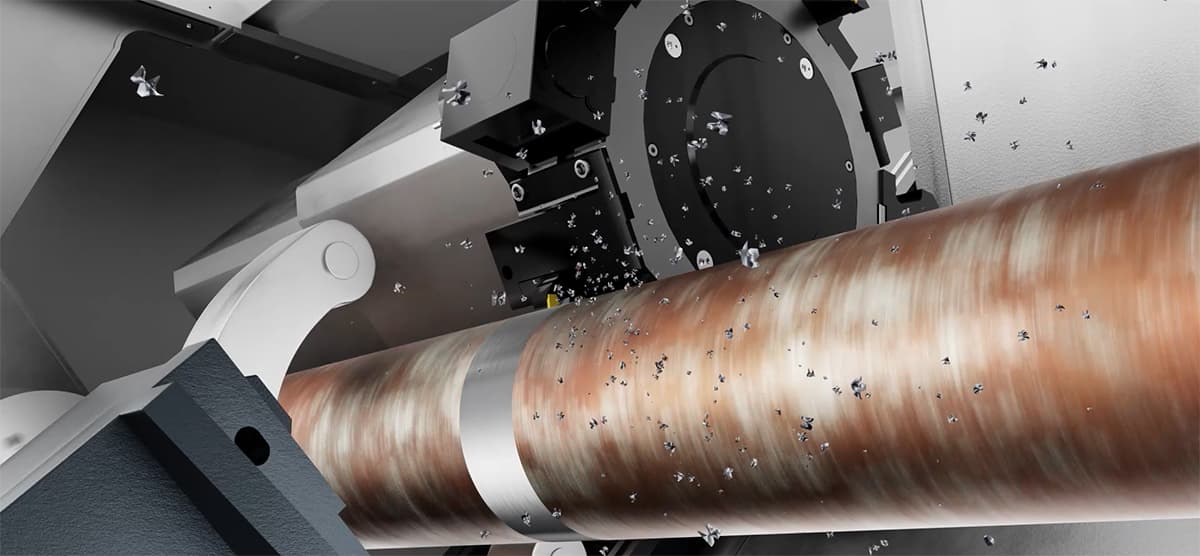

Oct 14 2025In CNC turning, setting cutting parameters correctly is crucial for machining quality, productivity, and tool life. Common parameters include:

- Cutting speed / Spindle speed (S)

- Feed rate (F)

- Depth of cut (ap)

- Step over / Radial depth of cut (ae)

Different materials, tooling, and machining strategies require different values. These parameters cannot be copied blindly but should be adjusted based on actual conditions and technical experience.

Spindle speed (n) and cutting speed (Vc) can be calculated using the formula:

n = (1000 × Vc) / (π × D)

- Vc: Cutting speed (m/min), determined by tool and workpiece material

- D: Workpiece diameter (mm)

- n: Spindle speed (rpm)

Example: For machining SUS304 stainless steel at Ø50 mm using carbide inserts with a recommended Vc of 100 m/min:

n = 1000 × 100 / (π × 50) ≈ 636 rpm

Feed rate (F) is defined as the distance the tool advances per minute, calculated as:

F = fz × n × z

- fz: Feed per tooth (mm/tooth)

- n: Spindle speed (rpm)

- z: Number of cutting edges

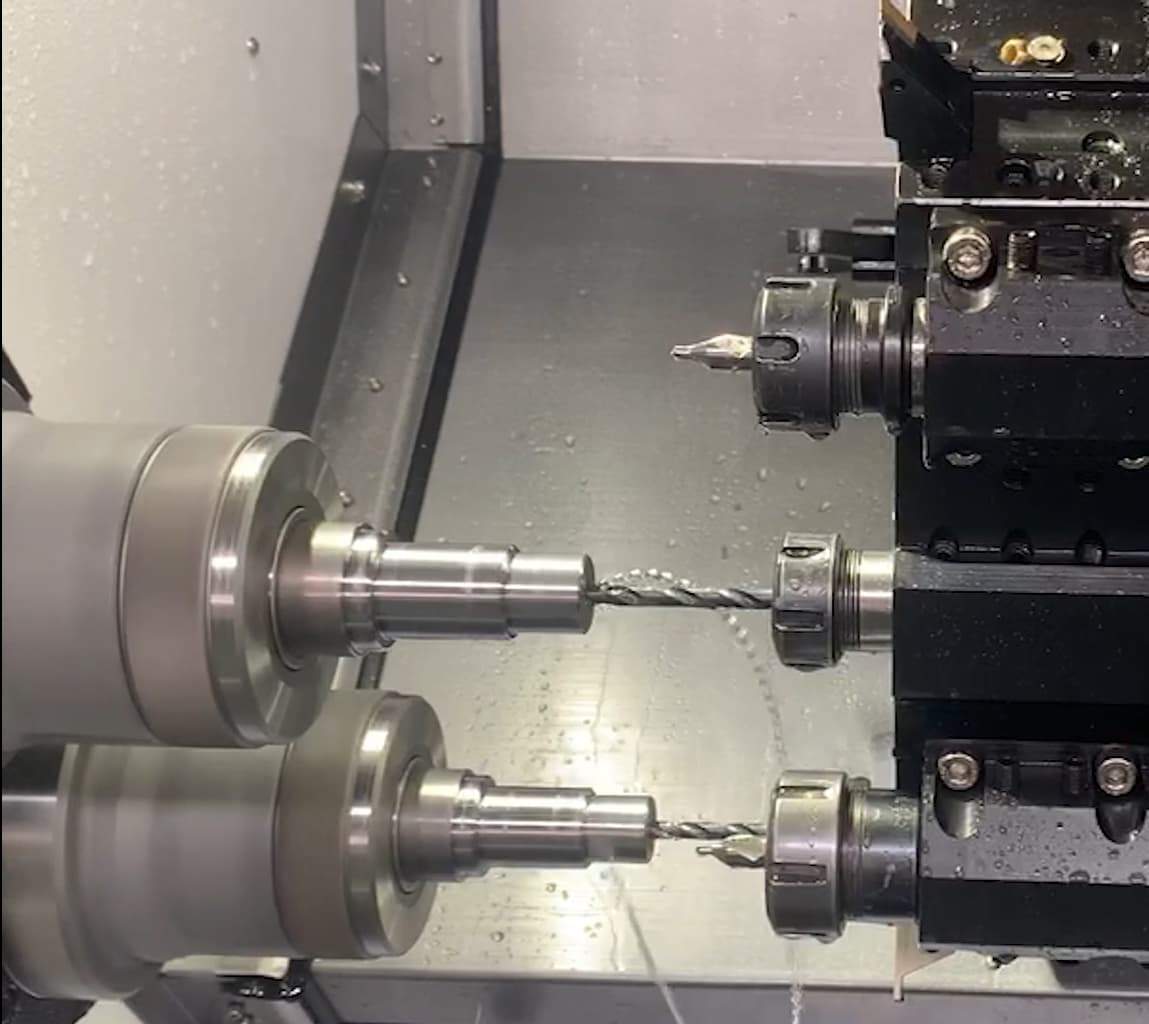

For roughing, higher feed rates are used, while finishing operations—especially internal cutting—require slower feeds to avoid chatter or dimensional issues. It is recommended to start with values provided by tool manufacturers and adjust based on actual results.

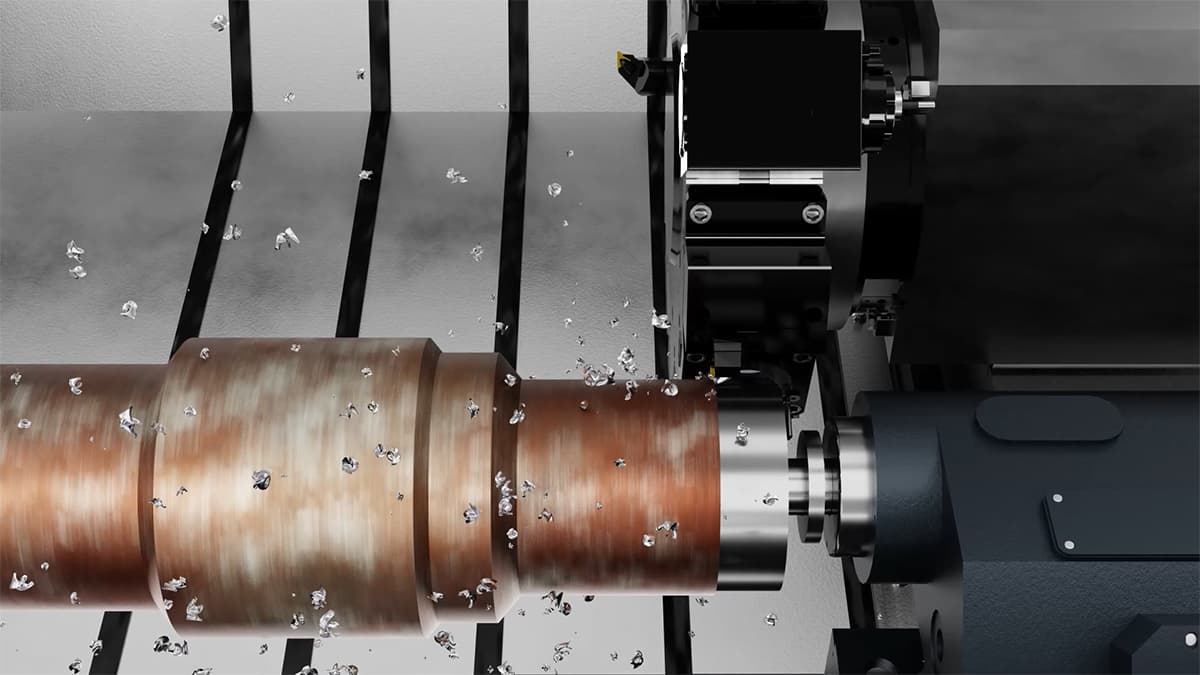

Depth of cut and engagement width also affect machining efficiency:

- Depth of cut (ap): Larger values increase material removal but require higher machine rigidity

- Step over (ae): Affects lateral load and depends on tool width and rigidity

- Too aggressive settings may cause chipping, while too light cuts may lead to tool rubbing or overheating.

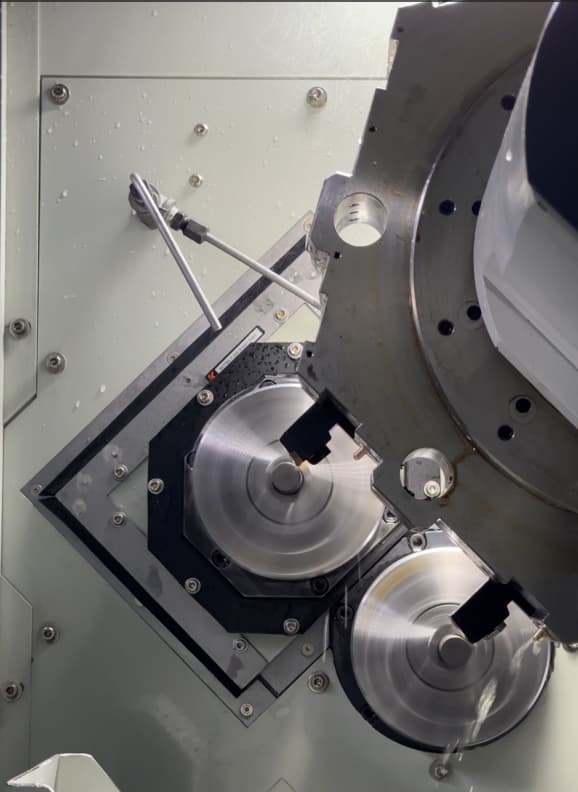

Force One recommends the following steps to determine optimal cutting conditions:

- Identify material and tooling type (carbide, ceramic, CBN, etc.)

- Refer to manufacturer data for initial Vc and fz

- Fine-tune based on machine rigidity (box way machines can take deeper cuts; linear guideways require lighter loads)

- Perform trial cuts and measure the results (dimension, surface finish, tool wear)

Force One models such as FCL-20I and FCL-20B are equipped with high-rigidity spindles and stable servo control systems, helping operators maintain accurate cutting parameters even at high speeds.

Good cutting parameter selection comes from:

- Knowledge of materials (hardness, thermal properties)

- Understanding tool performance (geometry, coatings, coolant strategy)

- Familiarity with machine capability and experience

We recommend establishing a cutting parameter log for each material and application. Long-term data collection helps form standard process templates, allowing for more scientific and consistent CNC machining operations.

Back

Back