Should I Choose a Slanted Bed or a Flat Bed for a CNC Lathe? Comprehensive Analysis: Evaluating Prod

May 05 2025

May 05 2025Importance of CNC Lathe Bed Design

In the mechanical design of CNC lathes, bed types are primarily categorized into slanted bed and flat bed configurations. The bed structure plays a crucial role in determining machining stability, production efficiency, and the level of automation. Each design has unique advantages, disadvantages, and suitable application scenarios, which merit thorough consideration before selection.

Slant Bed CNC Lathe: Features and Advantages

The slant bed lathe adopts a triangular rigid-body design, offering superior structural stability. Its angled turret and slide arrangement utilizes gravity to facilitate efficient chip removal, thereby minimizing chip accumulation. This reduces accuracy degradation and lowers maintenance frequency, making slant beds an excellent option for precision machining.

Key characteristics of slant bed lathes include:

Optimized rigidity and tool stability: The inclined layout enhances spindle support and tool positioning, ensuring superior clamping rigidity during high-speed cutting.

Efficient chip management: By leveraging the inclined structure, chips naturally fall away from the machining area, reducing interference and cleaning downtime.

Space efficiency for automation: The compact, streamlined layout makes slant beds ideal for integration with robots, automatic feeders, and loading/unloading systems.

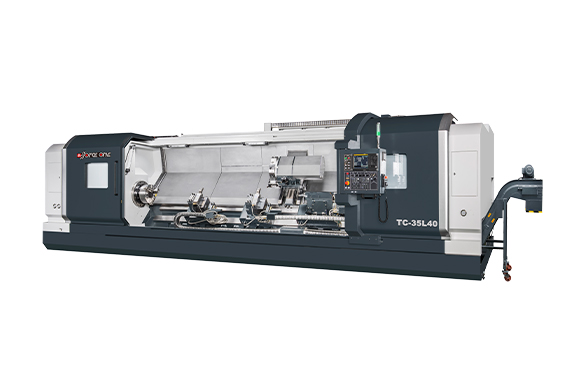

These features make slant beds an excellent choice for composite machining, high-volume production, and automated manufacturing lines. Notably, Force One's FCL and TC series are representative models that dominate mid-to-high-end precision manufacturing applications.

Flat Bed CNC Lathe: Features and Applications

The flat-bed lathe, while simpler in design, maintains its relevance, especially for niche tasks. With a symmetrical body, parallel spindle and slide arrangement, and relatively lower manufacturing costs, flat beds provide practical solutions for certain machining scenarios.

Key advantages include:

Open working space: The parallel structure enhances accessibility and visibility, especially useful for handling larger or long-axis components. Stable heavy-duty cutting performance: Flat beds excel in environments requiring low-speed machining, heavy cutting operations, or manual supervision.

Cost-effectiveness: The simpler structure is economical, making flat beds suitable for budget-sensitive applications such as technical education or small-scale/manual-dominant industries.

Even though slant beds dominate the contemporary CNC machine market, flat bed lathes remain valuable for tasks like heavy casting, maintenance convenience, and specialized fixture setups. Force One also offers customizable flat bed solutions, including options like reinforced guide rails or hydraulic tailstocks, to improve both rigidity and machining capabilities.

Slanted Bed vs. Flat Bed: Factors to Consider

When choosing the ideal CNC lathe, the specific machining requirements and operational contexts should serve as primary considerations:

Slant Bed CNC Lathe:

Best for high-speed, precision machining and mass production.

Designed for easy integration with automation modules, such as robotic systems.

Superior chip management and structural rigidity ensure stable operations for tasks requiring high demand.

Flat Bed CNC Lathe:

Suitable for large workpieces, heavy-duty cutting, or long-axis machining.

Particularly beneficial in operations requiring manual intervention and monitoring.

Offers cost advantages in initial investment while remaining robust for low-speed, high-load applications.

Force One leverages extensive expertise in product design and manufacturing to assist clients in selecting the most suitable bed structure. By tailoring solutions to specific application needs, we ensure clients achieve optimal performance and cost-effectiveness for their CNC machining setup.

Back

Back