Indirect Effects of Make in India and PLI Scheme: Growth Potential for Precision Machinery

Aug 11 2025

Aug 11 2025The Make in India policy and the Production Linked Incentive Scheme (PLI) are driving the transformation of India9s manufacturing sector, creating significant growth potential for the precision machinery industry.

Overview of the Make in India Policy

Policy Objectives

Since 2014, the goal has been to increase the manufacturing sector's contribution to GDP from approximately 17% to 25%

Key Sectors

Focuses on 25 key industries, including automobiles, aerospace, power, and machinery

Strategic Directions

Investing in infrastructure, simplifying regulations, and integrating supply chains to establish India as a global manufacturing hub.

Production Linked Incentive Scheme (PLI)

The PLI Scheme (Production Linked Incentive Scheme), launched in 2020, targets 14 key manufacturing sectors and encourages businesses to invest more in India through output-linked subsidies.

- Subsidy Duration: Each sector receives subsidies for a period of 5 years

- Total Budget: The total allocation for the scheme is approximately 1.97 trillion (around 24 billion USD)

- Policy Core: The main focus of the scheme is to strengthen India's export capacity and global competitiveness

The initial effects of the PLI scheme

538

Approved Projects

By 2024, the total number of approved projects

1.61 T

Attracting Investment

Approximately 19.4 billion USD

14 T

Generating Output

Approximately 168.7 billion USD

1150 K

Creating Jobs

The number of new job openings created

However, the manufacturing sector still accounts for only around 12314% of GDP, falling short of the 25% target. This indicates that the policy9s impact remains concentrated in specific industries.

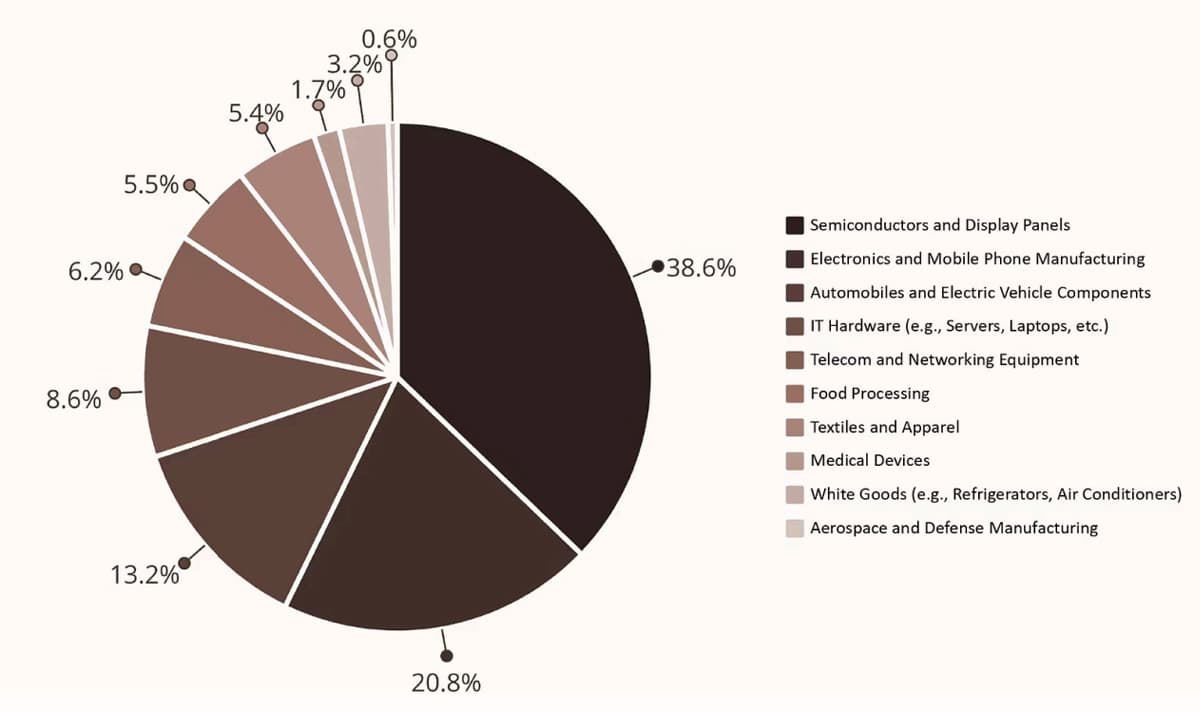

PLI Scheme: Subsidy Allocation by Sector

Indirect Benefit Pathways for Precision Machinery

| Beneficiary Industries | Driven Demand |

|---|---|

| Electronics and IT Manufacturing | CNC machining centers, high-precision cutting tools, jigs and fixtures |

| Automotive / Electric Vehicles | Motors, gear reducers, and other high-precision metal processing |

| Aerospace and Defense | 5-axis machining, composite material processing, mill-turn machines |

CNC machine tools are estimated to account for approximately 85% of the market, with the overall market expected to achieve a compound annual growth rate (CAGR) of 12%.

Opportunities for Manufacturers to Enter the Market

Local Supply Chain Formation

International brands such as Ceratizit have gradually established local supply chains in India. The increasing demand for localized key components like controllers, cutting tools, and jigs presents an opportunity for companies to enter the manufacturing chain.

Acceleration of Smart Manufacturing Adoption

Under the pressure of policy and capacity upgrades, Indian companies are beginning to invest in automation transformations. Applications such as CNC integration, tool-changing modules, and sensor and monitoring systems are rapidly gaining popularity. Manufacturers can provide comprehensive solutions.

Large Space for Technology and Talent Collaboration

Indian technical talent still generally lacks the skills for operating and maintaining high-end equipment. Manufacturers can establish brand trust and cultivate local engineers and service systems through models such as technology centers and industry-academia collaborations.

Strategic Outlook: New Bases for Long-Term Development

Make in India and the PLI Scheme are strengthening India's manufacturing foundation and attracting global supply chain restructuring. Although precision machine tools are not directly subsidized, they have benefited from the diffusion of demand driven by industrial upgrades.

For manufacturers, India is no longer just a sales market for equipment but a new strategic base for long-term development in manufacturing, technology, and brand value.

Back

Back