| ITEM | VHMT-13 |

|---|---|

|

Spindel spc. |

CYTEC M21-45°x10,000 rpm HSK-T100(milling spindle) 53 KW |

|

Working area |

X-asis travel: 2000 Z-asis travel: 2000 Y-asis travel: 1300 |

| Workpiece maximum rotation diameter | 2000 |

| Table size | D1320(STD.) / D1320(OPT.) /D1500(OPT.) |

|

C axis speed |

300 |

|

Maximum table load |

3000 |

|

Chip disposal |

Drag link/slat band conveyor |

|

CTS |

40 |

|

Tool magazine |

60T |

|

Tool size (diameter x length) |

250X500 |

|

Tool weight max. |

25 |

|

Rapid traverse X / Y / Z |

30/30/24 |

| Machining Method | Number of Processes | Number of Machines | Machining Time (8HR/Day) |

| VHMT-13 | 3 |

All-in-One Multi-Tasking Machine (Vertical/Horizontal/Boring/Turning/5-Axis |

6 Days |

| Traditional Machining | 11 | Gantry, Vertical Lathe, Horizontal, Gantry 5-Axis |

20 Days |

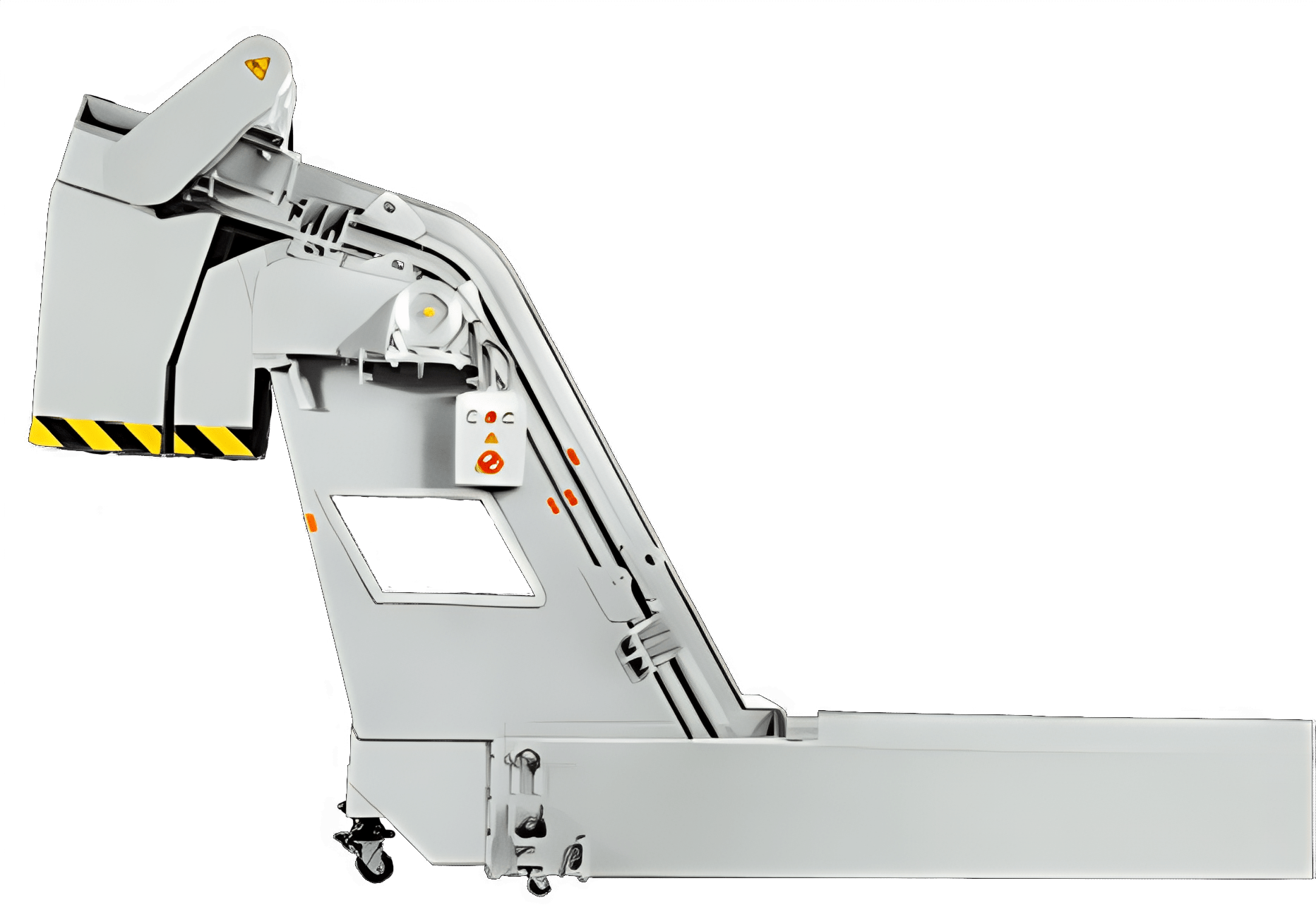

Track-Type Chip Conveyor(OPT.)

The track-type chip conveyor is installed inside the machine bed,

positioned on both sides of the worktable. It transports chips to

the third chip conveyor at the rear of the machine, which then

unloads the chips into the collection bin.

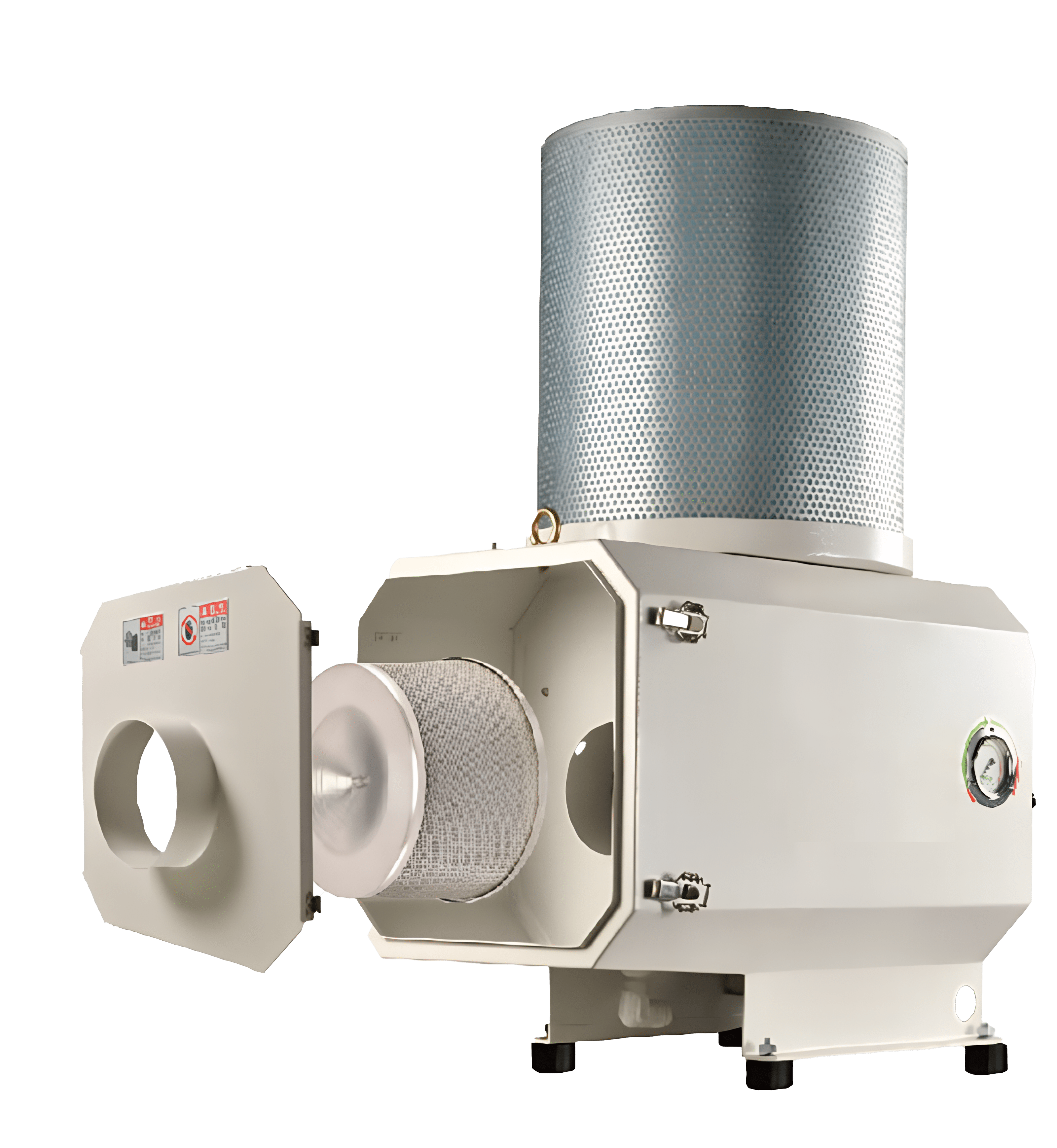

OIL MIST COLLECTOR(OPT.)

The oil mist collector uses advanced separation technology to efficiently capture oil mist generated during machining, reducing air pollution and improving workshop environment quality. Recovered cutting fluids can be recycled, saving costs and extending equipment lifespan, making it the perfect blend of environmental and economic benefits.

HOLLOW BALL SCREWS WITH COOLANT SYSTEM (OPT.)

The hollow ball screw cooling system can significantly reduce the thermal temperature rise position accuracy error caused by screw friction during machine movement, thereby improving the positioning accuracy of the machine.

Prev

Prev