Guide to CNC Rail Selection: Box Way vs Linear Guideway From Rigidity to Precision: Comprehensive Analysis

May 05 2025

May 05 2025

Importance of CNC Guideway System

The guideway system is a critical motion support mechanism in CNC lathes and machining centers, influencing rigidity, machining precision, speed, and machine longevity. Typically divided into two main forms—Box Way and Linear Guideway—the guideway system directly impacts production efficiency and product quality. Choosing the right type of guideway system is essential for achieving optimal performance in specific applications.

Box Way: The Best Choice for Rigidity and Stability

The Box Way guideway features a sliding surface structure processed directly on the machine bed, typically made of cast iron and finished with hand scraping to create an oil film for lubrication. Its high contact surface and rigid design make it ideal for heavy cutting operations and stable positioning of large workpieces.

Key Features:

- Superior rigidity and load distribution:

Box Ways can withstand high cutting forces and eccentric machining while absorbing vibrations effectively, resulting in enhanced machining stability and improved surface quality. - Ideal for heavy-load operations:

For machining materials such as cast iron and forged components, Box Ways offer excellent rigidity, preventing deformation or positional shifts during machining. - Higher lubrication needs and slower speed:

The sliding friction structure results in a higher friction coefficient (approximately 0.2), which limits movement speed and necessitates frequent lubrication and maintenance for extended service life.

Linear Guideway: Precision and Speed Leader

Linear Guideways utilize rolling elements such as balls or rollers, significantly reducing friction by converting metal-to-metal contact into rolling contact with a friction coefficient as low as 0.05. This design excels in high-speed motion and precise positioning.

Key Features:

- High-speed, high-precision machining:

Linear Guideways enable rapid movement with low friction, making them ideal for tasks such as mold finishing, complex contour machining, or high-speed material processing (e.g., stainless steel and aluminum). They also contribute to reduced energy consumption. - Accurate positioning for mass production:

Linear Guideways offer smooth movement and quick acceleration/deceleration, making them perfect for automated production lines performing quick tool changes—essential for high-volume manufacturing. - Lower resistance to vibration:

Linear Guideways are more sensitive to vibration and impact, making them unsuitable for heavy cutting or machining with large tools. Excessive vibration may lead to accuracy drift or damage.

Box Way vs Linear Guideway: How to Choose?

Force One specializes in both Box Way and Linear Guideway configurations, providing tailored solutions to meet diverse machining requirements. Here’s a comparison of the most suitable applications based on their respective strengths:

Box Way:

Recommended Applications:

Heavy cutting and cast iron machining: Ideal for high-load, large workpiece machining such as forged components.

High stability requirements: Suitable for rigid positioning and low-speed machining.

Representative Models:

Force One FCL Box Way machines.

TC large slant-bed lathes.

FLA, FAN, FAH Series flat-bed lathes for large-scale machining.

Linear Guideway:

Recommended Applications:

High-speed machining: Perfect for volume production of stainless steel or aluminum components with quick tool changes.

Multi-axis or rapid positioning needs: Ideal for automated environments involving mass production.

Representative Models:

Force One FCL Series Linear Guideway Models, such as the FCL-20I milling-turning machining center.

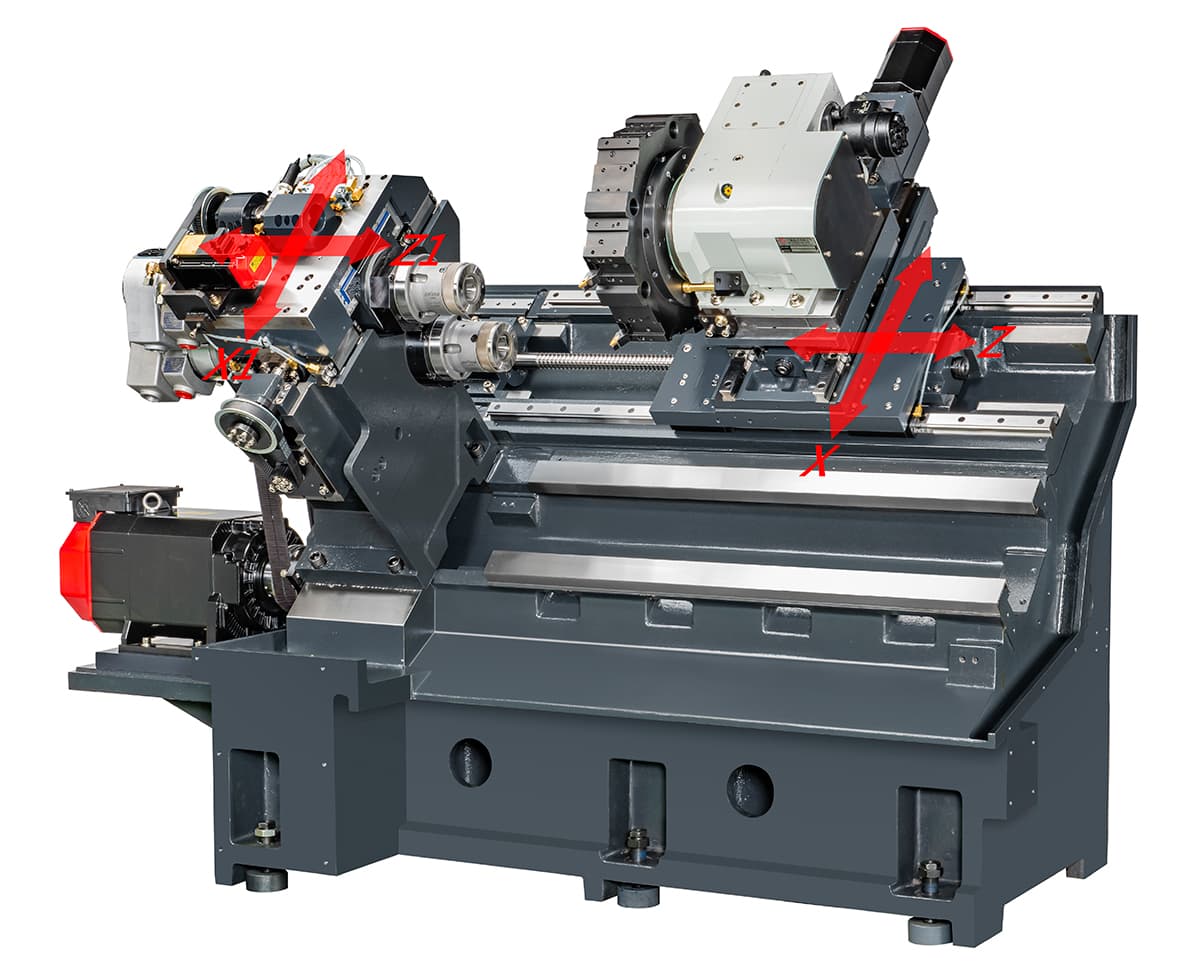

Hybrid Guideways: Balancing Rigidity and Speed

For specific machining demands, Force One also offers hybrid guideway systems, where, for example, the X-axis uses Linear Guideways for speed while the Z-axis uses Box Ways for rigidity. This combination achieves a balance between stability and fast movement while managing costs effectively.

Guideway Selection Core: Application-Centric Choices

Both Box Ways and Linear Guideways excel in their respective applications, without any absolute superiority. The key lies in choosing the configuration that best meets your machining needs:

Box Way: Focuses on high rigidity, heavy cutting, and stability.

Linear Guideway: Excels in high-speed machining and precise positioning.

When production requirements are carefully considered and paired with professional technical integration, you can establish a highly efficient and high-quality machining solution tailored to your needs.

At Force One, our product designs provide comprehensive technical support and customization options for Box Ways, Linear Guideways, or hybrid systems, helping you achieve your machining goals efficiently.

Back

Back