How Does a CNC Lathe Work? A Complete Guide to Key Components and Their Functions

Dec 04 2025

Dec 04 2025A CNC (Computer Numerical Control) lathe is an automated machine tool that performs precision cutting operations based on computer programming. It holds the workpiece on a rotating spindle while the turret or tool slide executes turning, drilling, or grooving operations with high precision.

With modern servo control and advanced CNC controllers, CNC lathes have become essential in high-efficiency and high-volume manufacturing environments.

Key Components of a CNC Lathe

| Component | Function |

|---|---|

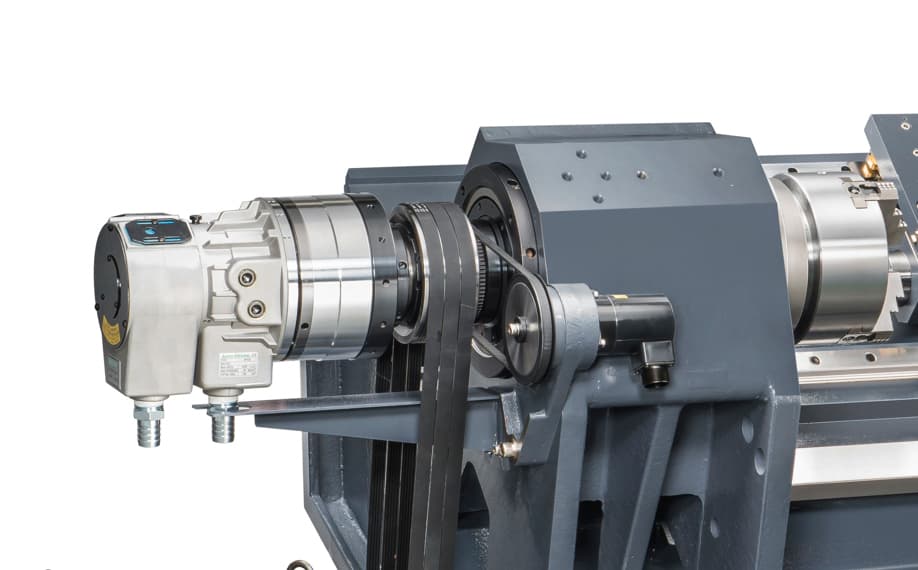

| Spindle | Drives the rotation of the workpiece. It is the central axis of turning operations. Some spindles support C-axis indexing. |

| Turret | Holds and switches tools during machining. Types include single, dual, and live tool turrets. |

| Tailstock | Supports long workpieces to prevent deflection. Can be manually or automatically positioned. |

| Bed | Provides the base structure. Determines overall machine rigidity. Can be flat-bed or slant-bed design. |

| Slide / Saddle | Controls movement of the turret or tools along linear axes (X, Z, and optionally Y). |

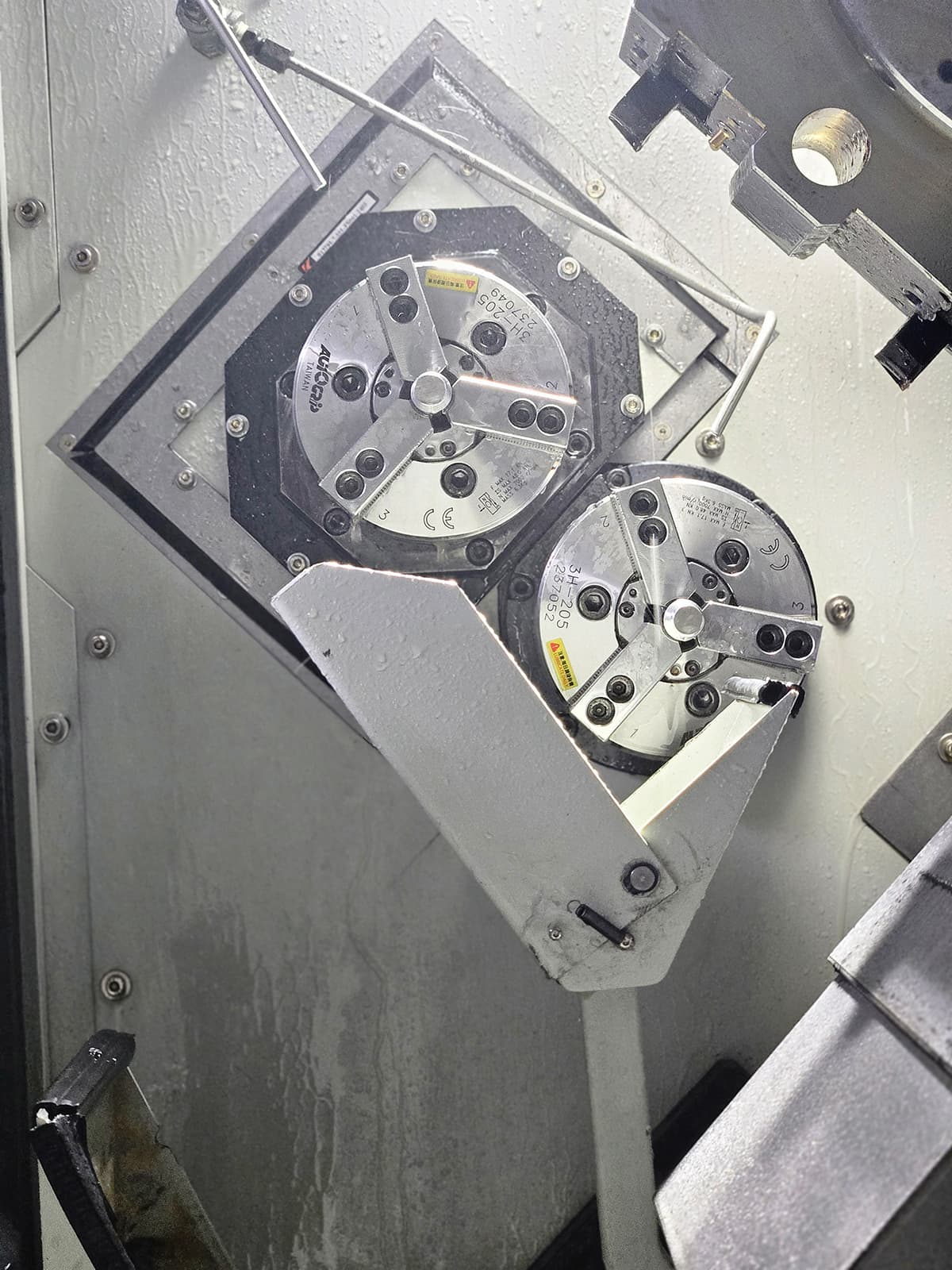

| Chuck | Clamps the workpiece securely. Can be pneumatic, hydraulic, self-centering, or custom types. |

| CNC Controller | Executes programs and servo commands. Interfaces include FANUC, Siemens, and others. |

| Coolant System | Provides fluid cooling to reduce heat, extend tool life, and maintain dimensional accuracy. |

| Auto Loading-Unloading System | Feeds and removes workpieces automatically using bar feeders or robots. |

| Chip Remove System | Removes metal chips to keep the machine clean and safe. |

| Part Catcher | Collects finished parts automatically to prevent drops or damage. |

Force One Machine Features (FCL Series Example)

- High-rigidity one-piece slant-bed design for stable cutting and effective chip removal

- Optional live tooling and C-axis on spindle and turret

- Modular turret options: single, sub-spindle, upper-lower turrets

- Compatible with FANUC, Siemens, or customer-specified controllers with conversational operation and multi-axis synchronization

Summary

Operating a CNC lathe is not just about writing code—it requires a deep understanding of each machine component. Knowing how the machine works helps you solve problems faster, plan more efficient setups, and improve machining accuracy. Force One encourages technicians to continuously study machine structure and build strong operator-machine synergy.

Back

Back